Research & Development

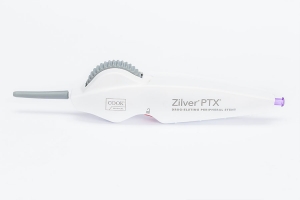

Tool and Gauge have a long history of working in collaboration with our clients in research and development of new products. Our dedicated R&D engineers understand product development and the critical role R&D plays in helping our customers get a component and/or product most suitable for manufacture / assembly.

Our customers trust our confidentiality on new product development programs including the generation of prototype tooling.

Advantages of collaborating on R&D projects with us include:

- Experienced design team

- Experience of both low and high volume tooling

- We facilitate testing, engineering design changes and product evaluation prior to investment in production moulds.

- We can provide short-run production volumes while a high-volume production mould is being manufactured

- Increases the overall speed of product to market allowing customers to capture greater market share and increase profitability.

Services:

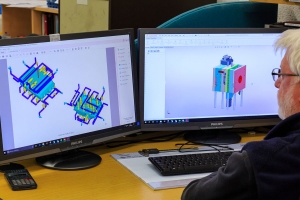

- Product Design

- Product Development together with clients

- Part Analysis & DFM (Design for Manufacture)

- Mould Flow Analysis / Design Development

- Injection Mould Design

- Design review prior to cutting steel

- Gauge & Fixture Design

- 3D Printing

- Prototyping

- Off-site storage of all design data

Projects:

Capital initiatives in this company are co-funded by the European Regional Development Fund and Enterprise Ireland under the Border, Midland and Western Regional Operational Programme 2014-2020.

Aims:

To continuously invest in the latest technologies to achieve the highest level of Precision. Our latest investment include a Roeders RXP 801 High speed machining centre for finish milling. Backed up by a Hurco VMX50Ti for semi finish machining.

Results:

Increased productivity and competitiveness was achieved as a result of this investment